AI in Engineering: Transforming How We Design, Build, and Maintain

Reading time

Date posted

Artificial intelligence has rapidly evolved from an experimental technology to a fundamental tool that is reshaping the engineering landscape. As AI capabilities continue to advance, engineers across disciplines are discovering new ways to leverage these technologies to solve complex problems, optimize designs, and create more efficient systems.

Engineering’s Vast Landscape and AI’s Role

Engineering encompasses numerous specialized fields, such as mechanical, civil, electrical, chemical, aerospace, biomedical, and many more. Each discipline presents unique challenges and opportunities for AI integration. While it would be impossible to cover all applications in a single overview, this blog post highlights a few examples that demonstrate how AI is transforming engineering practices across various sectors.

Key Areas Where AI is Revolutionizing Engineering

Predictive Maintenance

One of the most impactful applications of AI in engineering is predictive maintenance. AI-driven systems monitor variables like temperature, vibration, and pressure in real-time, analyzing patterns to detect early warning signs of equipment issues. These systems then alert operators to schedule maintenance at optimal times, with main benefits being:

Reduced downtime and emergency repairs.

Lower maintenance costs.

Extended machinery lifespan.

Major companies, like BMW and Shell, have successfully implemented AI-driven predictive maintenance, demonstrating significant operational improvements across automotive, oil and gas, and aviation industries.

“Predictive maintenance is an innovative strategy that uses artificial intelligence (AI) to keep a close eye on machinery performance in real-time, helping to spot potential failures before they happen. When these early warning signs are detected, AI can notify operators, giving them the chance to schedule maintenance at a time that works best, ultimately preventing costly downtime.“

– Yadav, H., and S. Yadav. (2025). Artificial intelligence in manufacturing and production. In Design Optimization Using Artificial Intelligence. CRC Press, Taylor & Francis.

Design Optimization

AI is fundamentally changing how engineers approach design challenges. Advanced algorithms can now:

Identify optimal configurations for complex systems.

Enhance product performance while minimizing material usage.

Reduce development costs through virtual testing.

For example, in materials science, AI helps create stronger and more durable materials by figuring out the best way to mix titanium with tiny reinforcing particles. It also analyzes how these enhanced materials resist wear and tear, leading to products that last longer.

Real-time Prediction in Computer-Aided Engineering (CAE)

The integration of AI with traditional CAE tools has introduced real-time prediction capabilities that allow engineers to:

Receive immediate feedback on design changes.

Understand complex performance implications without waiting for lengthy simulations.

Explore more design iterations in less time.

This convergence creates solutions with massive impact across engineering fields due to their generic and scalable nature.

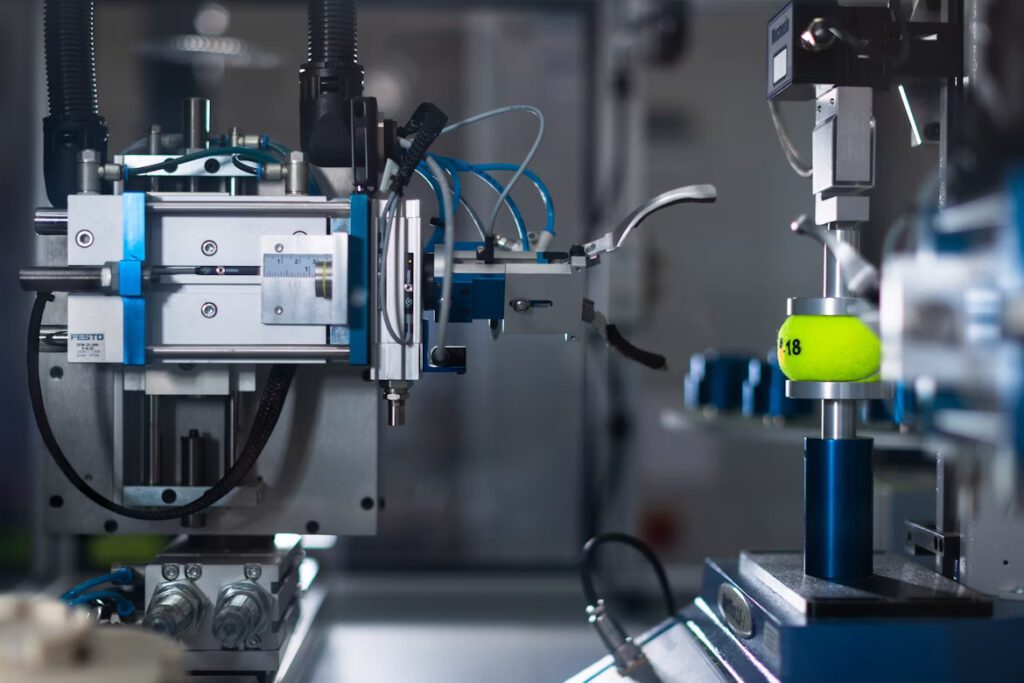

Manufacturing Process Enhancement

AI optimizes manufacturing processes in several key ways, including:

Process parameter optimization, with AI helping manufacturers determine optimal settings for equipment when creating and strengthening parts, particularly for complex processes like Wire EDM where electrical currents cut metal with precision.

Quality assurance automation, as AI-powered visual inspection systems can detect microscopic defects in components, ensuring higher quality standards while reducing manual inspection requirements.

Workflow optimization, thanks to machine learning algorithms that identify bottlenecks in production lines and optimize resource allocation (labour, machinery, materials), improving efficiency and reducing waste throughout the manufacturing process.

“Advanced techniques are necessary to convert data collected at different stages of the manufacturing process into insightful knowledge for smart manufacturing. Data-driven methods derived from machine learning are a core component of this approach.”

– Romagnoli, J. A., L. Briceño-Mena, and V. Manee. (2024). AI in Chemical Engineering: Unlocking the Power Within Data. CRC Press, Taylor & Francis.

Supply Chain and Logistics Optimization

AI is transforming supply chain management through:

Anticipatory logistics, with single-step forecasting replacing traditional two-step supply chain management.

Inventory optimization, aided by AI-driven forecasting which incorporates traditional supply chain data with external factors.

Perishable goods management, which minimizes waste through optimized routing that takes road conditions into consideration.

Sustainable Engineering Applications

AI is playing a crucial role in addressing environmental challenges, offering aid with the following:

Climate change mitigation, with algorithms analyzing climate data to predict patterns and evaluate strategies.

Waste management, thanks to the way AI optimizes collection routes and improves recycling through computer vision sorting.

Energy efficiency, as AI can predict renewable energy generation and optimize smart grid distribution networks

Agricultural Engineering

Deep learning models like CNNs (Convolutional Neural Networks) are revolutionizing precision farming through:

Automated crop disease detection and classification.

Soil moisture analysis and irrigation optimization.

Yield prediction and harvest planning.

Financial Engineering

Financial engineering uses advanced computer models to predict stock prices more accurately. Here’s how these modern approaches work:

Combined prediction methods, with financial experts now using a blend of traditional statistical models (ARIMA) and modern AI techniques (LSTM) to better forecast stock prices, similar to getting weather predictions from multiple sources for a more reliable forecast.

Different models for different patterns. Traditional models are good at spotting regular patterns like seasonal trends, while AI models can detect complex relationships that aren’t obvious to the human eye or traditional statistics.

By combining different approaches to work together, they can produce more reliable predictions than either could achieve alone, helping investors make more informed decisions about when to buy or sell stocks.

“Neural networks have proven to be highly adaptable in a variety of fields, such as banking and healthcare. Neural networks are used in healthcare to identify patterns in medical imaging data, which increases the accuracy of diagnosis. By identifying intricate market patterns, they improve predictive analytics in the financial industry.”

– Nanjundan, P., P. V. Indu, and L. Thomas. (2025). Navigating the Ethical Landscape of Artificial Intelligence: Challenges, Frameworks, and Responsible Deployment. In Artificial Intelligence Technologies for Engineering Applications. CRC Press, Taylor and Francis.

Implementation Framework for AI in Engineering

Successful AI implementation in engineering follows a methodical approach:

Define specific objectives and challenges.

Determine domains where AI can support goals.

Gather and preprocess relevant data.

Select appropriate AI algorithms (neural networks, fuzzy logic, genetic algorithms).

Ensure seamless integration with existing systems.

Develop KPIs to measure impact.

Incorporate feedback loops for continuous improvement.

Key considerations include flexibility and scalability, integration of diverse data types, and ensuring AI models provide explainable justifications for their predictions.

The Changing Role of Engineers

As AI continues to evolve, the engineering profession is undergoing significant transformation.

Shifting Focus to Higher-Value Activities

AI excels at handling repetitive, rules-based tasks, allowing engineers to focus on more complex, analytical, and creative work. Behind every AI system are highly-skilled professionals who develop and maintain these technologies.

New Skill Requirements

To thrive in this AI-enhanced environment, engineers need:

Data literacy and understanding of AI/ML concepts.

Systems thinking to integrate AI components with traditional engineering systems.

Knowledge of specialized AI applications in their discipline.

Challenges and Considerations

Despite its tremendous potential, AI integration presents several challenges:

Data quality and availability, with AI systems requiring substantial amounts of high-quality data.

Safety and performance assurance, as critical systems demand rigorous scrutiny and validation.

Ethical considerations, prompting engineers to address any potential bias, ensuring transparency and accountability throughout AI-powered processes.

The Future of AI in Engineering

Looking ahead, we can expect:

Further specialization of AI tools for specific engineering disciplines.

More autonomous engineering systems capable of self-optimization,

Knowledge graph-based systems enhancing recommendation and decision support.

Advanced pattern recognition approaches inspired by human cognition.

Conclusion

This piece has only scratched the surface of how AI is transforming the vast field of engineering. Each engineering discipline offers countless opportunities for AI integration, from civil engineers using machine learning for structural health monitoring, to biomedical engineers leveraging AI for prosthetic design.

The examples highlighted here represent just a small fraction of the ongoing revolution. As these technologies continue to mature, engineers have an unprecedented opportunity to build better, more sustainable systems more rapidly and effectively than ever before. The key to success lies not just in adopting AI tools, but also in reimagining engineering processes to fully leverage their capabilities across all engineering disciplines.